Even though defects are very rare, almost any batch of product can contain rejects. There will be rejects even after a quality control has been carried out and all detected defects have been eliminated. Perfect products only exist in a perfect world: that is why we aim to keep the deviations in our products within certain limits. Even though the quality guarantee systems used by packaging manufacturers are becoming more and more efficient thanks to the use of innovative technologies such as electronics and laser technology, there is always room for further improvement; every production process offers the possibility of developing new quality standards. A buyer always expects perfect products, although manufacturers cannot expect the supplier to supply them exclusively with perfect goods. But since the buyer does not want products with (too many) defects, he wants to control whether the purchased goods have a consistently high quality.

A complete control of the functionality of each individual product is impossible. Products would be far too expensive or directly unusable, as the product would be destroyed if too many test methods were used. For this reason, the method of "Acceptance Sampling" (random sampling to check whether the product quality is acceptable) was developed. Acceptance Sampling is a statistical quality control method, i.e. a middle ground between complete control and no control at all. Acceptance Sampling was born before the beginning of World War II, when the US Army had to determine which ammunition lots were acceptable and which had to be rejected as rejects. The tested ammunition was destroyed in the process. From this, the US Army developed Military Standard 105-D, where some rounds were tested representative of the ammunition lot, so that the other rounds from the lot could be trusted to work on the battlefield. This could ultimately make the difference between life and death.

The testing method according to this military standard 105-D led to a statistical sampling method used throughout the world called the AQL. The AQL tables are static tools that product and quality testers can make use of. Using the AQL tables, quality assurance inspectors can determine what sample size will produce reliable results and what standards of acceptance and rejection to apply.

The resulting inspection lot, in which representative samples (with a certain sampling frequency) are selected from a certain quantity of product (a lot) and tested to determine the acceptance or rejection of a product lot, is called an acceptance or sampling plan. This plan must comply with DIN ISO 2859 Part 1. The AQL, defined as the lowest quality level still accepted, is thus a statistical procedure for determining the quality of a product batch.

To determine the maximum number of reject units (i.e., the acceptable number of reject products), the quality inspector must know the following data:

-

the size of the product lot

-

The inspection level

-

The size of the randomly selected inspection lot

-

The so-called AQL percentage

To determine the correct sampling plan and acceptance/rejection level, quality inspectors mainly use two AQL tables:

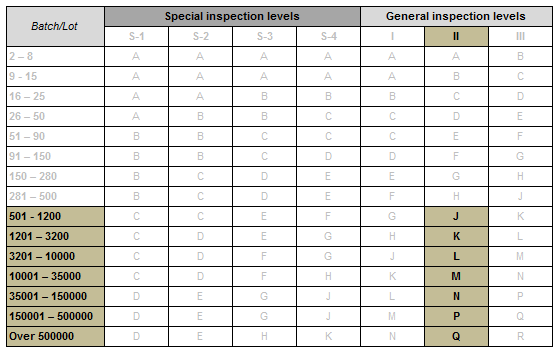

The first table is used to determine which "key letter" to use given the inspection level and size of the product lot.

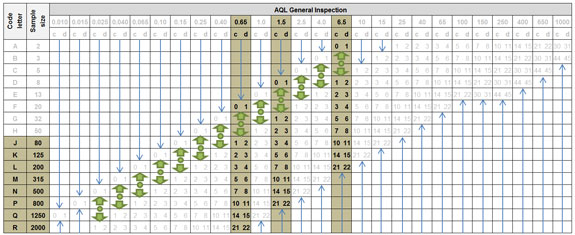

The second table is then used to determine the size of the product lot and the maximum number of defects allowed based on the AQL key letter.

Table 1 - Code numbers for the sample size according to DIN ISO 2859-1

The inspection level most frequently applied to pressed glass bottles in general is inspection level II.

Table 2 - Simple sampling plan for a standard inspection in accordance with DIN ISO 2859-1

The most commonly used classification for defects in pressed glass and the associated AQL percentage are as follows:

-

Class 1 defect: critical defect; results in an AQL percentage of 0 -> packing material no longer usable.

-

Class 2A defect: severe defect; leads to an AQL ratio of 0.65 -> considerably reduced usability of the packing material

-

Class 2B defect: severe defect; leads to an AQL-ratio of 1.5 -> partially reduced usability of the packing material

-

Class 3 deficiency: minor deficiency leads to an AQL deficiency ratio of 6.5 -> serviceability of the packing material reduced to some extent

During a quality guarantee inspection, an internally open glass bubble (deviation reference number 14.05.11) was detected in two product batches of 550,000 pressed glass bottles. According to the currently valid Defect Evaluation List, this is a Class 2A defect, for which an AQL percentage of 0.65 applies. What is the correct sample size and acceptable number of defects?

Product lot with 550,000 bottles of pressed glass:

The inspection level is defined as General Inspection Level II. The key letter is therefore "Q". (Table 1)

Accordingly, the size of the sample randomly selected from the total lot is 1,250 units. (Table 2)

Class 2A deficiency: severe deficiency; results in an AQL deficiency percentage of 0.65.

The acceptable number of defective bottles is a maximum of 14 with an AQL percentage of 0.65 (Table 2).

The non-acceptable number of defective bottles is 15 or more at an AQL percentage of 0.65 (Table 2)

Results of the Count for Lot 1 (Demonstration):

The quality controllers found the following number of defective bottles:

-

12 bottles with various class 2A defects

-

10 bottles with various class 2B defects

-

12 Class 2A defects are below the maximum allowable number of defects (14).

-

10 Class 2B defects are below the maximum allowable number of defects (21, see Table 2).

Result: Product Lot 1 is released/approved as none of the limits applicable to the two defect classes (2A and 2B) are exceeded.

Results of the count for lot 2 (demonstration):

The quality controllers found the following number of defective bottles:

-

14 bottles with various class 2A defects

-

22 bottles with various class 2B defects

-

14 Class 2A defects equal the maximum acceptable number of defects (14).

-

22 of class 2B exceed the maximum acceptable number of defects (21, see Table 2).

Result: Product Lot 2 is rejected/retracted because at least one of the limits applicable to the two defect classes (2A and 2B) is exceeded in this lot.

The examples shown in the applied counting rules and AQL proportions are for clarification purposes only.

Learn more?

Would you like to learn more about our product range or do you have any questions? Do you need an individual offer or information about ordering, delivery and payment conditions? Contact us by phone, email or live chat.