When you need to meet the highest quality standards

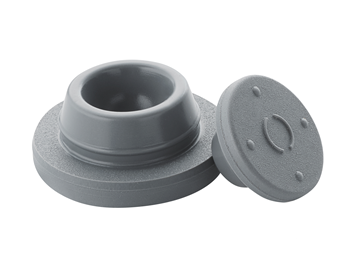

Daikyo D Sigma® offers high-quality elastomeric components for injectable pharmaceuticals designed to reduce particulates, lower patient safety risks, and decrease variability. Daikyo D Sigma® components combine advanced technologies and a long history of industry expertise.

Particle contamination has become a hotly debated quality issue. As a result, the regulatory burden for particle-free manufacturing (freedom from visible particle contamination) and the absence of foreign particles and chemical or physical contaminants has become a challenge for the industry. To meet these ever-increasing quality demands, West and Daikyo are pleased to introduce Daikyo D Sigma® - a superior quality of elastomer components.

Daikyo D Sigma® components combine several critical quality attributes, starting with the tightest particle specification in the Daikyo portfolio. Daikyo D Sigma® elastomer components combine advanced technology and know-how to deliver the tightest particle specifications in the Daikyo portfolio and 100% dimensional verification. This helps reduce variability and mitigates potential risks to patient safety.

Daikyo D Sigma® components are available in ready-to-use validated(DAIKYO RUV®) and ready-to-sterilize validated(DAIKYO RSV®) grades. The variety of packaging configurations ranges from DAIKYO RUV® Small Packs (500 / 1,000 pieces) to standard commercial configurations in STERILizableBAG ™ or portion bag packaging, as required.

-

Vision inspected at 0.01 mm² particle sizes, Tighter AQL, Particle Testing performed to ISO 8871-3 - Minimize drug safety risk and improve patient protection

-

Components are washed and sterilizable(RSV®) or sterile and ready-to-use(RUV®) - Reduce your manufacturing footprint, streamline processes and outsource risk

-

Automated 100% verification - Reduced risk of variability

-

State-of-the-art, clean rubber formulation - Low extractables and volatiles

-

Flurotec® film- Forms a protective barrier between the drug and its closure, reducing stopper sticking and clumping

-

RB2 coating technology- An alternative to silicone that reduces subtractive particle reduction associated with silicone, improved machinability

Learn more?

Would you like to learn more about the products of Daikyo Seiko, Ltd. or do you have any questions? Do you need an individual offer or information about ordering, delivery and payment conditions? Contact us by phone, email or live chat.