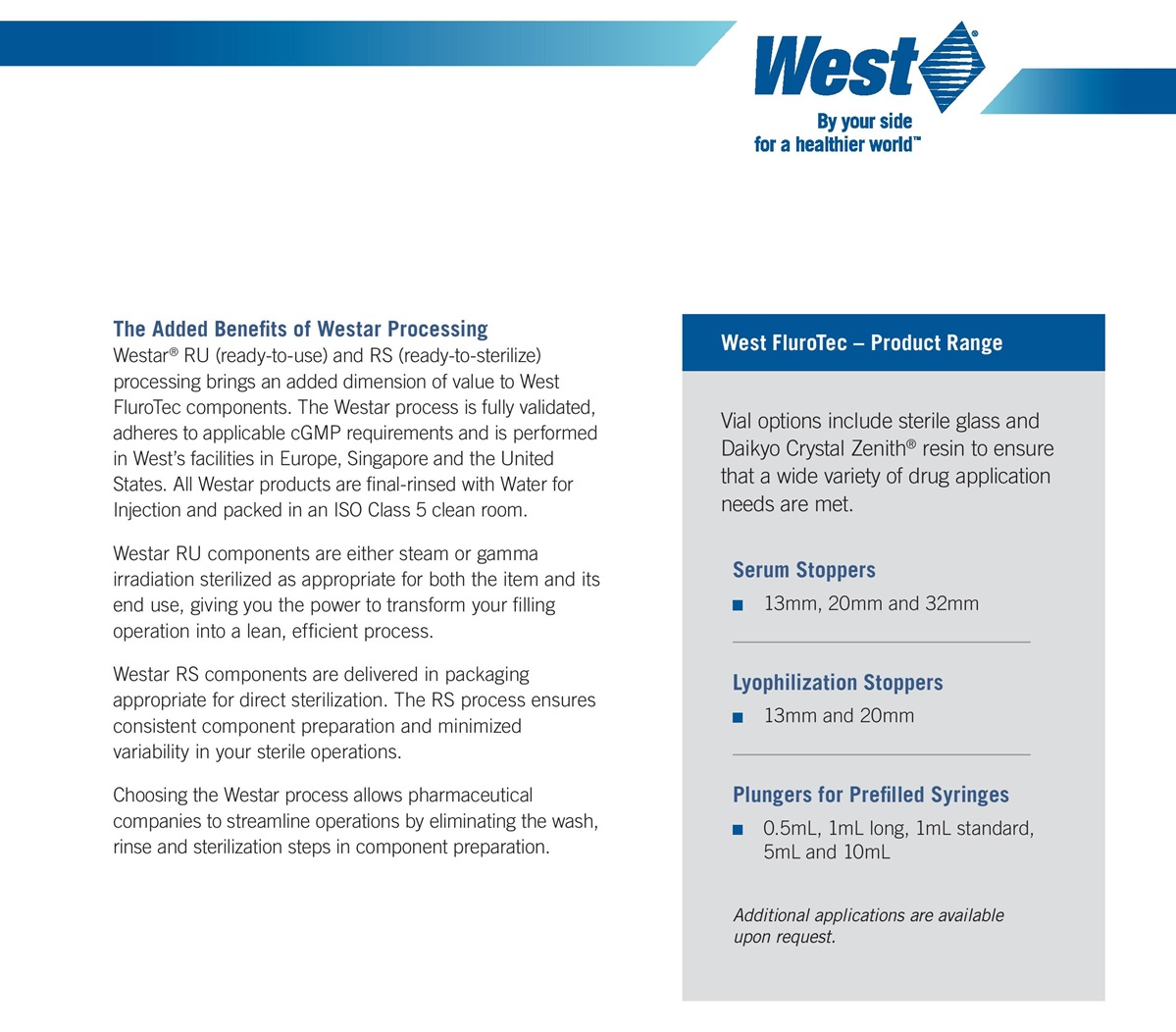

West plungers are the first choice for protecting drugs in prefilled syringes or cartridges from contamination by providing an effective barrier that minimizes interaction between the drug and the closure while maintaining the integrity of the container closure. The plungers are available in 0.5 ml, 1 ml, 1 - 3 ml and 5 ml sizes.

West plungers are the first choice for protecting drugs in prefilled syringes or cartridges from contamination by providing an effective barrier that minimizes interaction between the drug and the closure while maintaining the integrity of the container closure. The plungers are available in 0.5 ml, 1 ml, 1 - 3 ml and 5 ml sizes.

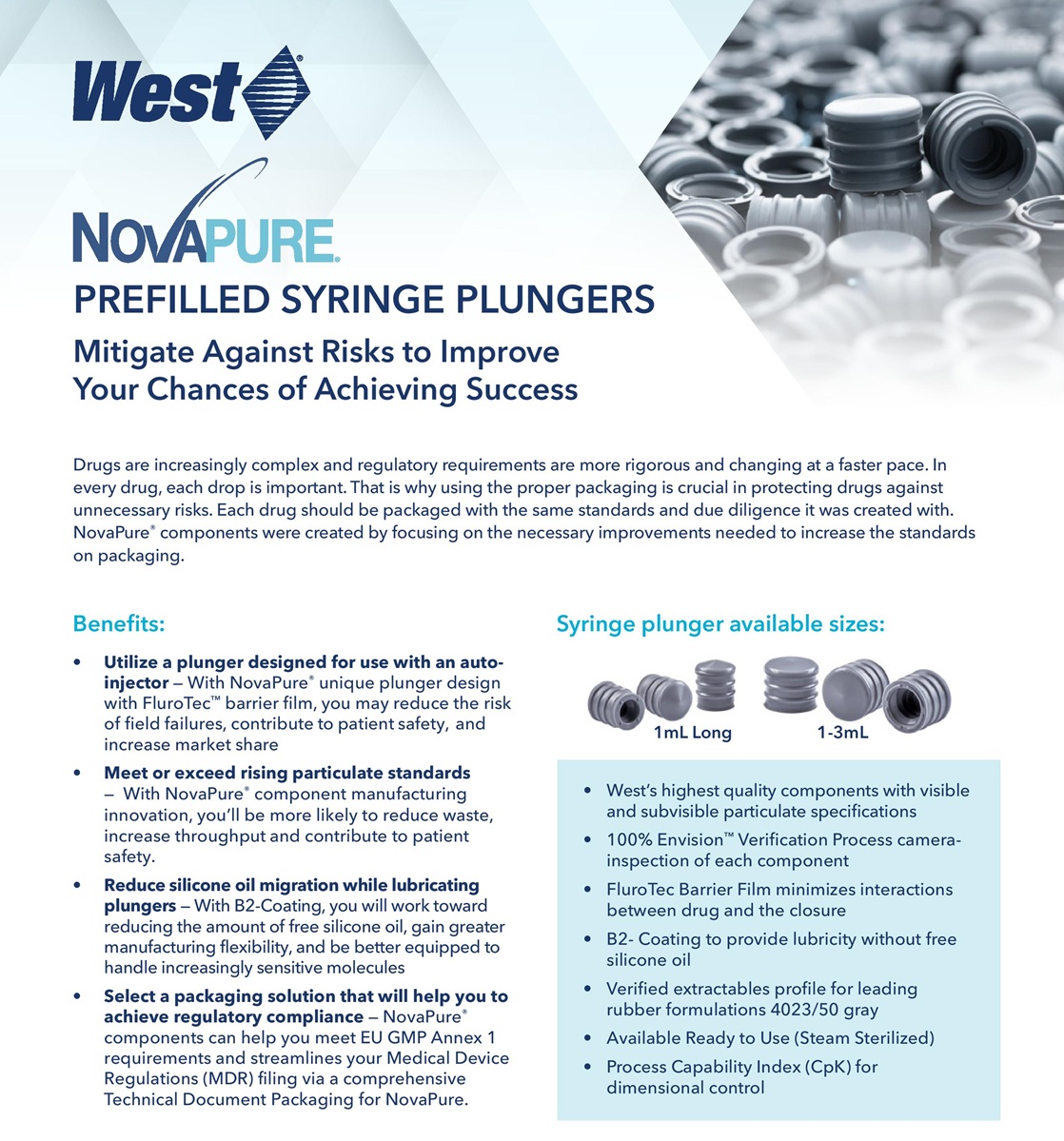

In the world of injectables, every component - especially the plunger - counts for biological stability, patient safety and regulatory reliability. With NovaPure® elastomer plungers, West offers a leading-edge product specifically designed to meet these stringent requirements.

Why NovaPure®?

Minimized compatibility risk:

- NovaPure plungers are based on state-of-the-art elastomer formulations, coated with the proprietary FluroTec® barrier film technology - significantly reducing rubber to drug interaction.

Consistent and predictable performance:

- Development principles from "Quality by Design" ensure that break-loose and extrusion properties are optimized and variation from part to part is minimized.

Strict quality controls & transparent release criteria:

- NovaPure is subject to demanding specifications (including extractables tests, 100 % visual inspection, cpk/ppm release) - for maximum safety in production and application.

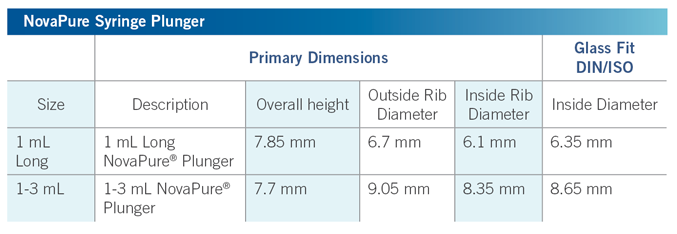

Versatile sizes for different requirements:

- Available as 1 mL long plunger as well as 1-3 mL plunger - ideal for diverse syringe formats.

Seamless integration into your process:

- West offers robust packaging options - from small volume shipping to bulk bags or ported bag systems - matched to modern fill-finish lines including RABS and isolators.

Your added value at a glance:

- Reduced risk of interactions with sensitive biologics

- Consistent and reproducible injection performance

- Highest quality standards and transparent release criteria

- Flexible packaging portfolio for your production processes

In the age of ever larger doses and higher viscosities, the selection of the right components for injection systems plays a decisive role - especially the cartridge plungers. With NovaPure® cartridge plungers, West offers a solution specifically for high-volume injectable systems that meets the highest standards of safety, compatibility and reliability.

Chemical barrier & reduction of interactions:

Chemical barrier & reduction of interactions:

- The plungers utilize West's state-of-the-art elastomer formulations combined with proven FluroTec® Barrier Film technology. This significantly minimizes unwanted interactions between the active ingredient and elastomer - a basis for maintaining the effectiveness and stability of biological substances.

Development according to Quality-by-Design (QbD):

- The design and manufacture of components follow a systematic, data-based approach ("Quality by Design"). As a result, critical parameters such as dimensional accuracy, consistency and process robustness are controlled from the outset.

Uniform conveying and gliding properties:

- NovaPure® cartridge plungers are designed for consistent break-loose and glide forces - essential especially for applicators, auto-injectors or modular dispensing systems for larger volumes.

Why choose NovaPure®?

- The requirements for biologics, higher doses and home-use systems are increasing - and so are the requirements for safe, reliable primary packaging.

- NovaPure® cartridge plungers help to harmonize stability, reproducibility and device performance.

- As part of an established system with FluroTec® components, West helps you minimize interactions, ensure the integrity of container systems and optimize your development process.

The fluoropolymer film prevents absorption and adsorption of the drug, an important advantage for maintaining the efficacy and shelf life of most drugs.

Advantages of West FluroTec® Plunger / Piston Plug:

-

Improve the shelf life of a packaged drug product

-

Reduce visible and invisible particles

-

Improve the compatibility of the closure and the drug product

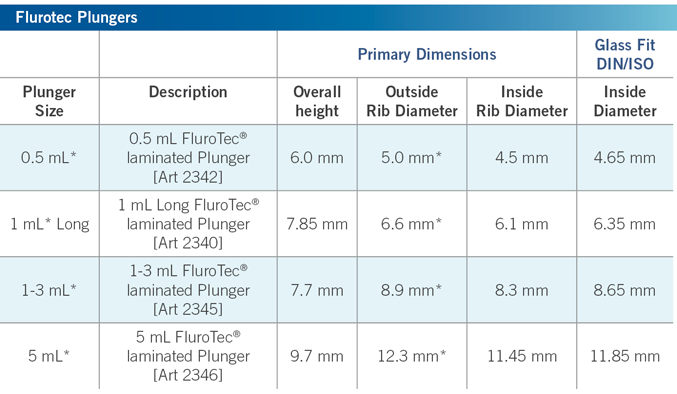

In modern injection systems, FluroTec® Cartridge Plungers bring the next generation of barrier technology to your primary packaging. Designed for demanding formulations and higher volume applications, they minimize interactions and ensure the integrity of your drugs - even in on-body or high volume applications.

Premium barrier thanks to FluroTec® film:

Premium barrier thanks to FluroTec® film:

- The FluroTec® coating (ETFE film) reduces adsorption and absorption of active ingredients, protecting the active ingredient from contamination.

High volume capability - especially 5-10 mL:

- The FluroTec® 5-10 mL Cartridge Plunger addresses the growing need for large-volume subcutaneous administration, e.g. in portable injection systems (on-body).

Innovative 1.5 mL version with double-sided coating:

- The FluroTec® 1.5 mL Cartridge Plunger is unique in its dual coating - simplifies process integration as no alignment orientation is required and enables applications in dual-chamber systems.

Ready-to-use & seamless integration:

- FluroTec® Cartridge Plungers are supplied as sterile, ready-to-use components - optimized for fill-finish lines with ported bags, RABS or standard bags.

Support for on-body / home therapy concepts:

- With the trend towards self-medication, the demand for devices that can administer large volumes is also growing. The FluroTec® 5-10 mL variant enables exactly this - and contributes to the shift from clinic therapies to the home.

If you have in your primary packaging:

- Minimize interactions

- Realize high volumes or novel device systems

- Consistent performance & easy integration

- Regulatory safety through proven technology

, then FluroTec® Cartridge Plungers from West are a first-class choice. They integrate seamlessly into your existing systems and offer a technically sound path to the future of your injectables.

Particle contamination has become a hotly debated quality issue. As a result, the regulatory burden of particle-free manufacturing (freedom from visible particle contamination) and the absence of foreign particles and chemical or physical contaminants has become a challenge for the industry. To meet these ever-increasing quality demands, Daikyo has developed Daikyo D Sigma®-Plunger, a high-quality plunger for glass syringes.

Particle contamination has become a hotly debated quality issue. As a result, the regulatory burden of particle-free manufacturing (freedom from visible particle contamination) and the absence of foreign particles and chemical or physical contaminants has become a challenge for the industry. To meet these ever-increasing quality demands, Daikyo has developed Daikyo D Sigma®-Plunger, a high-quality plunger for glass syringes.

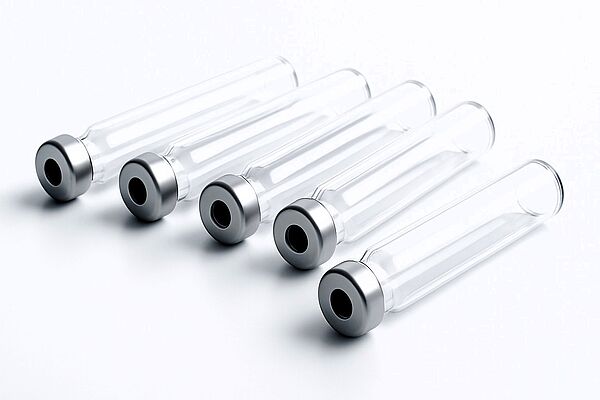

Packaging options for the 1 ml Long Daikyo D Sigma® Plunger

Rubber formulation: D 21-7H grey - Daikyo Flurotec® + RB2-40

Safe, compatible solutions for prefilled syringes:

Safe, compatible solutions for prefilled syringes:

Safety, quality and precision are crucial when filling and using sensitive medicines. West's Rigid Needle Shields (RNS) and Tip Caps offer reliable protection for prefilled syringe systems - developed to meet the highest requirements in the pharmaceutical and biotechnology industries.

Maximum safety for product and user:

West`s Rigid Needle Shields reliably protect needles from damage and minimize the risk of accidental puncture injuries. The combination of a sturdy plastic sheath and elastomer inner core ensures optimum grip and safe handling in automated filling processes. The matching tip caps close the syringe securely and maintain the integrity of the active ingredient until use.

Compatible with leading syringe systems:

West components are fully compatible with common standards of prefilled syringes - whether they are fixed or embedded needles. This flexibility enables seamless integration into existing production lines and packaging processes.

Designed for regulatory compliance:

The materials meet the strict requirements of the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP). The specially developed elastomers are free from natural rubber and ensure high chemical stability - for maximum product safety and reliable active ingredient integrity.

Quality you can trust:

West stands for uncompromising quality. All Rigid Needle Shields and Tip Caps are manufactured under controlled conditions and tested for consistency, leak tightness and process reliability. The result: components that are trusted by leading pharmaceutical and biotech companies worldwide.

Learn more?

Would you like to learn more about West Pharmaceutical Services products or do you have any questions? Do you need an individual offer or information about ordering, delivery and payment conditions? Contact us by phone, email or live chat.